Design & Engineering

The initial design aka master mold, which is carved by hand out of ABS plastic, as this adds rigid properties, provides an idea of weight, and action.

Originally started as a fishing component manufacturer called RODCANDY, we gradually transitioned into the world of CUSTOM LURES. while working with professional Anglers from around the globe, we realized a need exists for lures that target Predatory fish species found around the world. Hence, BRAZEN TACKLE, REVENGE Custom Baits was formed.

We are on a mission to set new standards, push creative boundaries and provide you with the perfect fishing lures.

The initial design aka master mold, which is carved by hand out of ABS plastic, as this adds rigid properties, provides an idea of weight, and action.

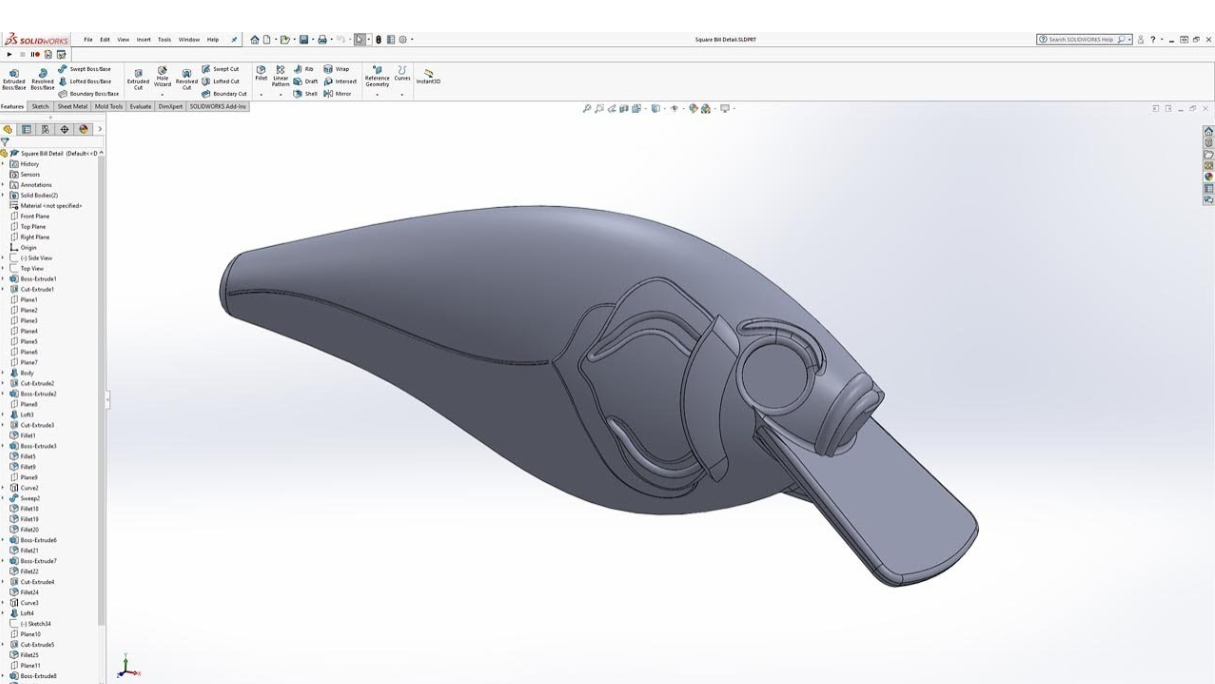

Post the initial carving, we then create a 3D model using 3D CADCAM

the Master mold is scanned and a duplicate is born through machine cutting which ensures the weight, size, and action are correct. Even though this is not the quickest or cheapest way to achieve similar results with the software and technology available. However we believe handmade products are best.

The first injection bodies are created and tested for integrity and harboring components. Tolerances must be exact for ballast, hook positioning and lip angle. Once product passes precise testing, production is complete

We use a process which melts the mold to fuse it together ensuring a unified unit.

At this point the lures are submerged into hot water which then quickly identifies any imperfections.

We strive on a painting process that focuses on detail and precision. Coats are applied one step, one layer at a time. Depending on the complexity and can have anywhere between 5-20 layers. We Currently offer over 400 color variations.

this is the final step, where a protective clear coat is added. Post the second quality control inspection, the lures are sent for packaging.